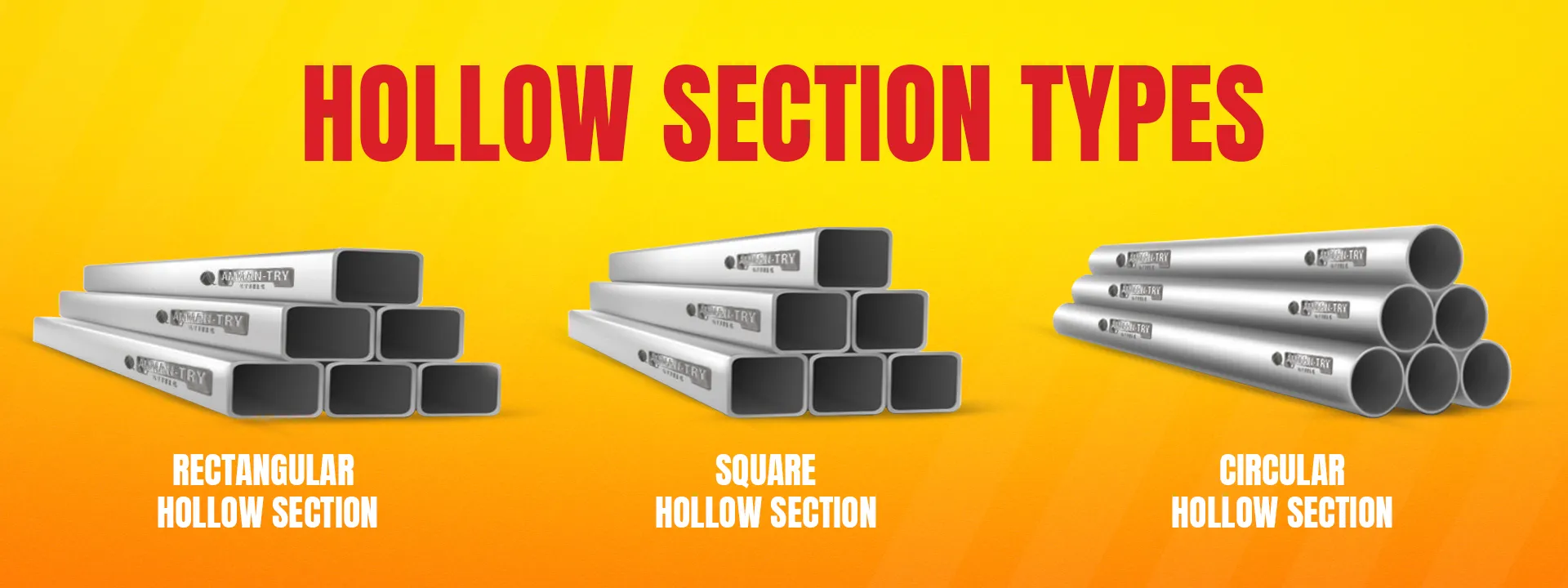

AMMAN-TRY – Steel hollow section manufacturer from South India The company offers an extensive range of steel hollow sections in various sizes, thicknesses, and grades to accommodate diverse construction needs. Our company’s hollow section is available in circular, rectangular and square shapes for all your construction needs. While producing the hollow sections including RHS, SHS & CHS), we strictly follow the industry standards with high quality. Our product range is available in various dimensions and thicknesses to meet requirements.

Square Hollow Section(SHS)

Our square hollow sections are consistent in dimensions and used in construction, machinery frames, & fencing and act like a middle-man between RHS and CHS. The flat surface of Square Hollow Sections (SHS) is flat, which not only makes it economically viable and highly weldable but also allows for easy customization and fabrication to meet specific project needs. SHS shares similar characteristics with Circular Hollow Sections (CHS), with proportional appearances formed in equilateral square hollow sections. It possesses high load-bearing characteristics and provides a vacant space that can be effectively utilized in various industries. Our square hollow sections are available in various grades, with sizes falling between 1 and 3.5 inches while maintaining international standards and all testing processes.

| Tube Size | Kg/ Mtr | Kg/Piece | No of Pieces/Ton | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| mm | Inch | 1.6 mm | 1.8 mm | 2.0 mm | 1.6 mm | 1.8 mm | 2.0 mm | 1.6 mm | 1.8 mm | 2.0 mm |

| 25 x 25 | 1 | 1.14 | 127 | 1.47 | 6.84 | 7.62 | 8.82 | 146 | 131 | 113 |

| 31 x 31 | 1.25 | 1.44 | 1.61 | 1.77 | 8.64 | 9.66 | 10.62 | 116 | 104 | 94 |

| 38 x 38 | 15 | 1.75 | 2 | 2.41 | 10.74 | 12 | 14.46 | 93 | 83 | 69 |

| 47 x 47 | 20 | 2.25 | 2.51 | 2.77 | 13.5 | 15.06 | 16.62 | 74 | 66 | 60 |

| 72 x 72 | 2.75 | 3.5 | 3.92 | 4.41 | 21 | 23.52 | 26.46 | 48 | 43 | 38 |

| 91 x 91 | 3.5 | 4.46 | 5 | 5.54 | 26.76 | 30 | 33.24 | 37 | 33 | 30 |

Circular Hollow Section(CHS)

Circular Hollow Sections (CHS) are widely utilized in structural applications due to their load-bearing capacity in all directions. Renowned for their durability and ability to withstand heavy loads and pressures, CHS products boast full certification and are suitable for low-temperature applications. Moreover, CHS facilitates cost-effective factory construction and lightweight structures.CHS also offers a significant advantage for building structures exposed to high wind or water currents. The grades of the circular hollow section, It is between 1 and 2.0 mm. It conforms to international standards, offering advantages for building structures exposed to high wind or water currents.

| Tube Size | Kg/ Mtr | Kg/ Piece | No of Pieces / Ton | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| mm | Inch | 1.6 mm | 1.8 mm | 2.0 mm | 1.6 mm | 1.8 mm | 2.0 mm | 1.6 mm | 1.8 mm | 2.0 mm |

| 25NB/33.8 OD | 1 | 1.05 | 1.19 | 133 | 6.3 | 7.14 | 7.98 | 159 | 140 | 125 |

| 32NB/42.50 OD | 1.25 | 133 | 1.5 | 168 | 7.98 | 9 | 10.08 | 125 | 111 | 99 |

| 40NB/42.5 OD | 1.5 | 1.6 | 1.85 | 2.07 | 9.84 | 11.1 | 12.42 | 102 | 90 | 81 |

| 50NB/60.2 OD | 2 | 2.04 | 2.3 | 2.56 | 12.24 | 13.8 | 15.36 | 82 | 72 | 65 |

| 65NB/76 OD | 2.5 | 2.63 | 2.96 | 3.3 | 15.78 | 17.76 | 19.8 | 63 | 56 | 51 |

| 80NB/88.7 OD | 3 | 3.22 | 3.61 | 4.04 | 19.32 | 21.66 | 24.24 | 52 | 46 | 41 |

| 10.0NB/113.9 OD | 4 | 4.01 | 4.5 | 5.03 | 24.06 | 27 | 30.18 | 42 | 37 | 33 |

Rectangular Hollow Section(RHS)

Rectangular Hollow Sections are utilized in the construction industry due to their dimensions and structural integrity. Available in different grades and materials, including various coatings, these sections provide aesthetic appeal and corrosion protection.

| Tube Size | Kg/ Mtr | Kg/Piece | No of Pieces/Ton | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| mm | Inch | 1.6 mm | 1.8 mm | 2.0 mm | 1.6 mm | 1.8 mm | 2.0 mm | 1.6 mm | 1.8 mm | 2.0 mm |

| 41 x 21 | 1.5 x 0.75 | 1.44 | 1.61 | 1.77 | 8.64 | 9.66 | 10.62 | 116 | 104 | 94 |

| 50 x 25 | 2 x 1 | 1.77 | 1.97 | 2.18 | 10.62 | 11.82 | 13.08 | 94 | 85 | 76 |

| 56 x 37 | 2.25 x 1.5 | 2.22 | 2.48 | 2.74 | 13.32 | 14.88 | 16.44 | 75 | 67 | 61 |

| 75 x 25 | 3 x 1 | 2.4 | 2.68 | 2.96 | 14.4 | 16.08 | 17.76 | 69 | 62 | 56 |

| 80 x 40 | 3 x 1.5 | 2.9 | 3,25 | 3.59 | 17.4 | 19.5 | 21.54 | 57 | 51 | 46 |

| 96 x 48 | 3.75 x 2.0 | 3.5 | 3.92 | 4.34 | 21 | 23.52 | 26.04 | 48 | 43 | 38 |

Uses Of Hollow Sections

Hollow sections cater to diverse construction applications, including roof shed structures, steel and staircase railings, house main gates, sheds, steel door and window frames, and warehouses.

Quality Check & Certificate

AMMAN-TRY ensures the quality of its products through rigorous testing of the chemical and mechanical properties of the manufactured steel pipes and tubes, conducted by the standards established by the Bureau of Indian Standards (BIS). The company employs experienced quality control managers, high-quality raw materials, specialized production processes, and modern testing equipment to maintain efficient quality standards at every stage of production.