Ensuring the structural integrity of buildings is crucial in a world where urbanization is drastically changing skylines. The integrity of structures is seriously threatened by earthquakes, a type of natural disaster that can happen suddenly. Earthquake Resistant TMT bars (Thermo-mechanically treated) are becoming an increasingly important component of resilient building designs as engineers and builders look for creative ways to reduce this risk.

Understanding Earthquake-Resistant TMT Bars:

TMT bars are a kind of reinforcement steel that is frequently used in buildings because of their exceptional strength and longevity. But not every TMT bar is made equally. The capacity of a structure to absorb and release seismic energy during an earthquake determines its seismic vulnerability. Earthquake Resistant TMT bars serve a purpose in this situation.

Thermo-Mechanical Treatment:

TMT bars that are resistant to earthquakes are made by a particular manufacturing process called thermo-mechanical treatment. To give the bars their distinct mechanical and chemical qualities, they must first be heated to high temperatures and then quickly cooled. As a result, the TMT bar is more resilient to seismic stresses and has increased strength and ductility. AMMAN-TRY follows the latest Belgium based Tempcore Thermo Mechanically Treated Process Technology with a perfect blend of strength and ductility that can withstand the Earthquake.

Ductility and Flexibility:

One of the main advantages of earthquake-resistant TMT bars is their remarkable ductility. One way to define “ductility” is a material’s ability to bend before breaking. Because of this attribute, TMT bars can absorb and distribute the energy produced during an earthquake, limiting the possibility of significant damage. TMT bars are elastic and can bend without breaking, which is important in areas that experience regular earthquakes.

Improved Weldability:

A building’s overall structural strength greatly depends on the quality of the TMT bars that are welded together. Improved weldability in the design of earthquake-resistant TMT bars guarantees a strong bond between various structural components. This increases the building’s overall stability and lowers the possibility that it may collapse during an earthquake.

Corrosion Resistance:

Corrosion frequently affects structural materials, especially in humid or close to the coast. Special alloys or chemicals that offer improved corrosion resistance are frequently coated on earthquake-resistant TMT bars. This ensures both the overall durability of the structure and the longevity of the reinforcement. AMMAN-TRY CRS TMT Bars reduces the cost of repairs that are caused due to corrosive damage and well suits for Earthquake regions

Benefits of Using Earthquake-Resistant TMT Bars:

Enhanced Safety:

The increased safety that earthquake-resistant TMT bars provide is the main benefit of using them in construction. TMT bars increase a building’s ability to withstand the lateral pressures produced by an earthquake, reducing the chance of collapsing and saving lives.

Reduced Maintenance Costs:

Over a structure’s lifetime, the corrosion-resistant qualities of these TMT bars help to lower maintenance expenses. In the long term, earthquake-resistant TMT bars are a cost-effective option since they considerably reduce the need for regular inspections and repairs owing to corrosion.

How do we identify earthquake-resistant TMT bars from the normal ones?

It is essential to distinguish between normal and earthquake-resistant thermo-mechanically treated (TMT) bars to maintain the structural integrity of structures located in seismically active areas. Remember the following details when distinguishing between regular and earthquake-resistant TMT bars.

Grades and Standards:

TMT bars that are meant to withstand seismic forces are made in accordance with certain grades and specifications. Governing bodies or other organizations have established standards in several countries that outline the qualities and attributes of materials that are earthquake-resistant. Seek TMT bars that fulfill or surpass these requirements. AMMAN-TRY is the first Steel Manufacturer in Tamil Nadu to produce 100% ISI marked products from inception. It made AMMAN-TRY the more trustable brand among the customers.

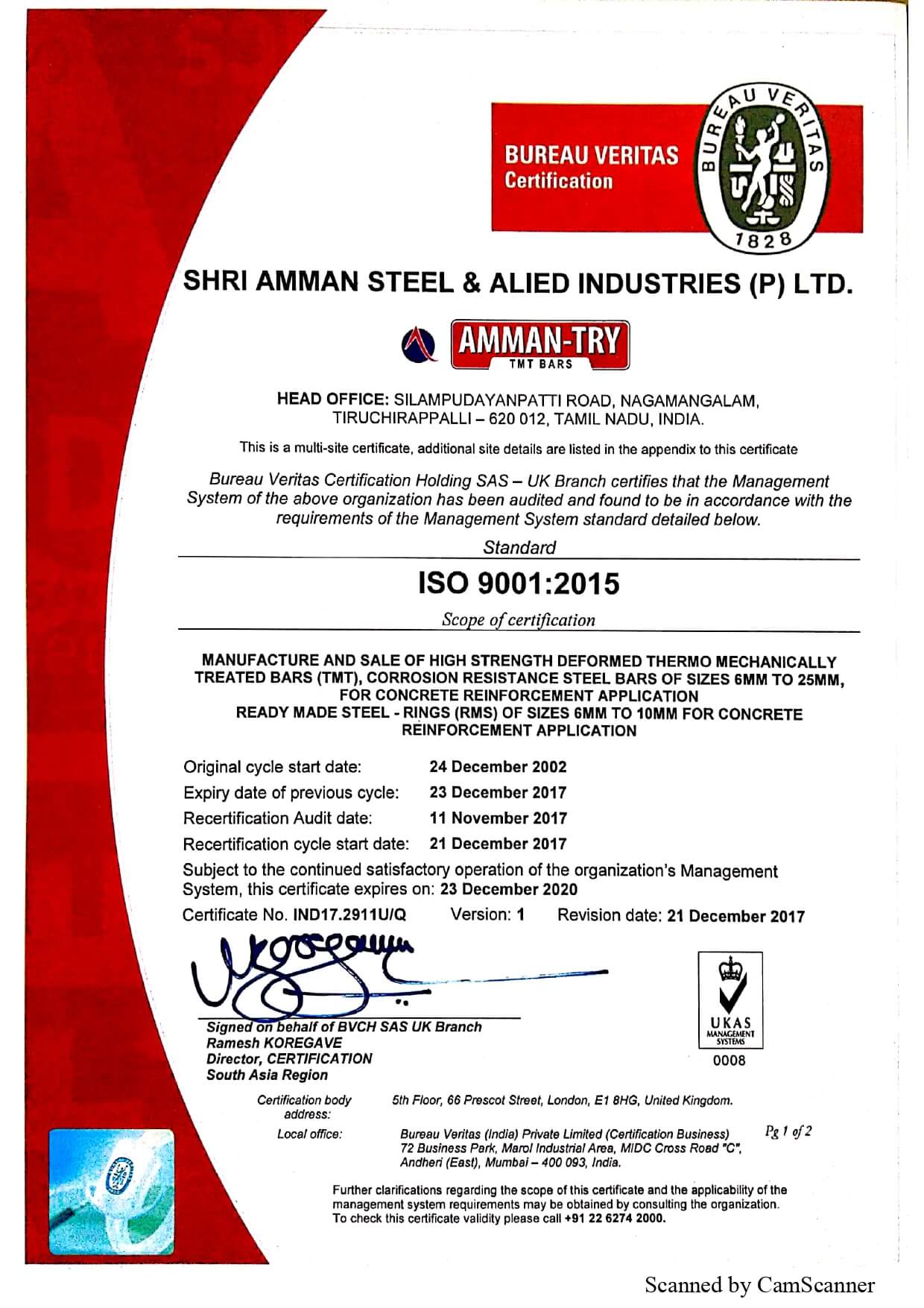

Certifications:

Reputable manufacturers of TMT bars resistant to earthquakes frequently receive certificates from appropriate regulatory bodies or quality assurance associations. AMMAN-TRY is one of the largest Steel TMT Bars manufacturers with 40+ years of experience holding ISO Certificates, PWD Certificates, TMT Bars Test Certificates, Omega Inspection & so. It all shows how AMMAN-TRY TMT Bars are helpful in standing against the earthquakes and other natural calamities.

Manufacturer Reputation:

It is crucial to select TMT bars from trustworthy manufacturers who have a reputation for creating high-quality building supplies. Examine the manufacturer’s track record, read client testimonials, and find out about their dedication to quality assurance and adherence to industry norms.

Consult with Structural Engineers:

Seek advice from construction experts or structural engineers whenever in doubt. They may help confirm that the selected materials fulfill the relevant specifications and offer advice on which TMT bars are suitable for a certain seismic zone. AMMAN-TRY having a separate team for Structural Consultant who help people regarding the construction structures and materials.

Finally, AMMAN-TRY TMT Bars are produced with highest yield strength and corrosion-resistant materials, which can be used in the zones that are prone to earthquakes or other vibrations of the Earth.