500 guarD

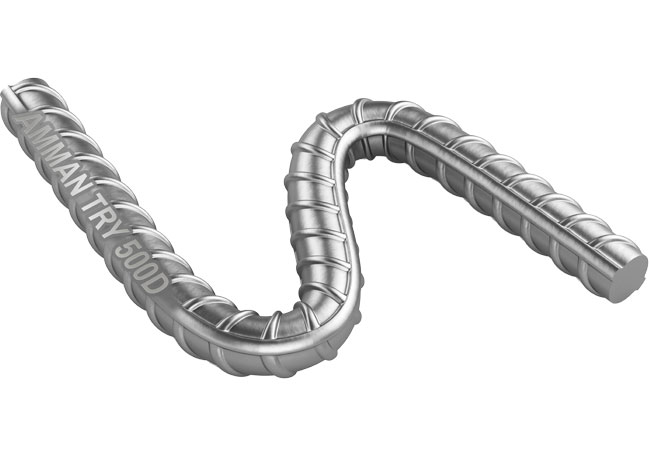

Expert believes that these two chemical components (S & P) will easily affect the steel bars by reducing their elongation and bendability, by which the building’s life becomes a question. To overcome this, 500 D was introduced by ISI. Compared to the ISI standards, our AMMAN-TRY “500 guarD” are made of even less S&P components for getting the following advantages. AMMAN-TRY has been contributing to the steel production of our Country for the past 40 years. And Introduced different types of Bars like Twisted Bars, TMT Bars, CRS Bars, and Rings. Considering the increasing growth of the building sector and safeguarding the Buildings for generations to come, AMMAN -TRY Group is happy and proud to launch “500 guarD”. Based on the advice from leading Engineers in the country and the expectations of the customers, this “500 guarD” bars are produced with high quality and strength.

WHY 500 guarD

Bendability

Our “500 guarD” bars are made of billet with low percentage Sulphur & Phosphorus, which posses excellent bendability and requires low power to bending the bars.

Earthquake Resistance

These bars are provided with balanced stiffness, Strength, and ductility to resist earthquakes. Our “500 guarD” provide very high strengths with higher elongation and ductility.

QUALITY GUARANTEED

AMMAN-TRY / TMT Bars are manufactured to the International standards and Indian standards IS: 1786, IS: 2830 and IS: 456 standards, and is also recognized by CEB.

EQUAL TO WORLD STANDARDS

AMMAN-TRY is a pioneer in the implementation of Thermo Mechanical Treatment Method by Tempcore Belgium Technology.

About AMMANTRY

AMMAN Steel Group started in 1978, has made remarkable progress over the past 40 years and it is now the leading steel producers. A group of Company, AMMAN Steel Corporation was initially a scrap retail and trade organization. AMMAN Steel Group soon expanded into the biggest integrated steel plant in the private sector in South India. It is one of the largest and most respected companies in South India with 2 Rolling Mill plants in Tamilnadu and 2 Steel making plants one in Puducherry and another in Andhra Pradesh. It is headquartered at Trichirapalli, Tamilnadu.

AMMAN Steel Group has grown over the years from a mere 25 dealers to more than 300 dealers now. This growth was possible only because of the cooperation and support offered by dealers. To be deserving, in return the AMMAN-TRY Steels make fine housing comfortable and affordable. AMMAN-TRY Steel is the AMMAN Steel Group’s Trade Mark and most popular brand in South India.

| Chemical Properties | Properties (%) | ISI Fe-500 | AMMAN-TRY 500 guarD |

|---|---|---|

| Carbon | 0.30 (Max) | 0.17 - 0.25 |

| Sulphur | 0.055 (Max) | 0.040(Max.) |

| Phosphorus | 0.055 (Max) | 0.040 (Max) |

| Sulphur + Phosphorus | 0.105 (Max) | 0.075 (Max) |

| Carbon Equivalent | 0.42 (Max) | 0.42 (Max) |

| Mechanical Properties | ||

| Properties (%) | ISI Fe-500 | AMMAN-TRY 500 guarD |

|---|---|---|

| Yield Strength (N/mm2) | 500 (Min) | 520 - 550 |

| Tensile Strength (N/mm2) | 545 (Min) | 620 - 690 |

| Elongation (%) | 12 (Min) | 18 (Min) |

| Total Elongation (%) | - | 8 (Min) |

| Bend Test ( Mandrel size) (<_20 mm) | 4D | 3D |

| Section Weight | |||||

| ISI | |||||

| Section | Min Wt. (Kg / Mtr.) | Normal Wt. (Kg / Mtr.) | Max Wt. (Kg / Mtr.) | ||

|---|---|---|---|---|---|

| 06 mm | 0.206 | 0.222 | 0.238 | ||

| 08 mm | 0.367 | 0.395 | 0.423 | ||

| 10 mm | 0.574 | 0.617 | 0.660 | ||

| 12 mm | 0.843 | 0.888 | 0.932 | ||

| 16 mm | 1.500 | 1.579 | 1.658 | ||

| 20 mm | 2.393 | 2.467 | 2.541 | ||

| 25 mm | 3.739 | 3.855 | 3.971 | ||